In the ever-evolving world of industrial manufacturing and logistics, efficiency and automation are key to achieving consistent and reliable operations. One such advancement in this space is the Hairise conveyor, which has revolutionized the way products are transported across production lines. The Hairise conveyor technology is designed to optimize workflow, reduce labor costs, and increase productivity. Through its highly adaptable and versatile design, the Hairise conveyor can be customized to fit various industrial applications, making it a staple in modern production environments. The Hairise conveyor systems are engineered with the latest materials and cutting-edge technology to ensure maximum durability, smooth operations, and minimum downtime. Whether you’re involved in assembly, packaging, or material handling, the Hairise conveyor offers a tailored solution for your needs. Furthermore, the Hairise conveyor can integrate seamlessly into existing systems, helping businesses streamline their operations with minimal disruption. It is this combination of innovation, reliability, and adaptability that makes the Hairise conveyor an ideal choice for industries looking to enhance their efficiency and productivity.

Key Features of Hairise Conveyor Technology

The Hairise conveyor technology offers a variety of features that set it apart from traditional conveyor systems. One of the standout features is its modular design, which allows for easy customization. The Hairise conveyor can be designed to meet the specific needs of various industries, whether it’s for handling delicate items, heavy-duty products, or even complex materials. The flexibility of the Hairise conveyor ensures that it can handle multiple applications within the same manufacturing plant, making it a versatile solution for industries across the board.

Another key feature of the Hairise conveyor is its ability to improve workflow efficiency. The system’s precise control mechanisms allow for smooth and consistent product movement, reducing bottlenecks and ensuring that production lines operate at maximum capacity. The Hairise conveyor is equipped with advanced sensors and controllers that provide real-time data on system performance, enabling operators to quickly identify and resolve issues before they impact production. Additionally, the Hairise conveyor integrates seamlessly with other automated systems, such as robotic arms, packaging machines, and sorting devices, which further enhances overall operational efficiency.

Benefits of Using Hairise Conveyor in Industrial Applications

The integration of the Hairise conveyor into industrial applications provides numerous benefits that directly contribute to increased productivity and operational cost savings. One of the primary benefits is its ability to handle high-volume production with ease. The Hairise conveyor can transport large quantities of materials or products quickly and efficiently, helping to speed up production cycles. This is particularly important in industries like automotive manufacturing, food processing, and electronics, where high throughput is crucial to meeting market demand.

Another significant benefit of the Hairise conveyor is its durability. Built with high-quality materials and designed to withstand harsh working conditions, the Hairise conveyor is engineered to last. This reduces the frequency of maintenance and replacements, which in turn lowers long-term operational costs. Additionally, the Hairise conveyor is designed to minimize downtime, as it requires less frequent maintenance and is equipped with fail-safe mechanisms to ensure continuous operation.

The Hairise conveyor is also known for its energy efficiency. Unlike traditional conveyor systems, which may consume significant amounts of power, the Hairise conveyor is designed with energy-saving features that help reduce electricity consumption. This makes it an environmentally friendly option for businesses looking to reduce their carbon footprint while still maintaining high levels of productivity.

Types of Hairise Conveyor Systems

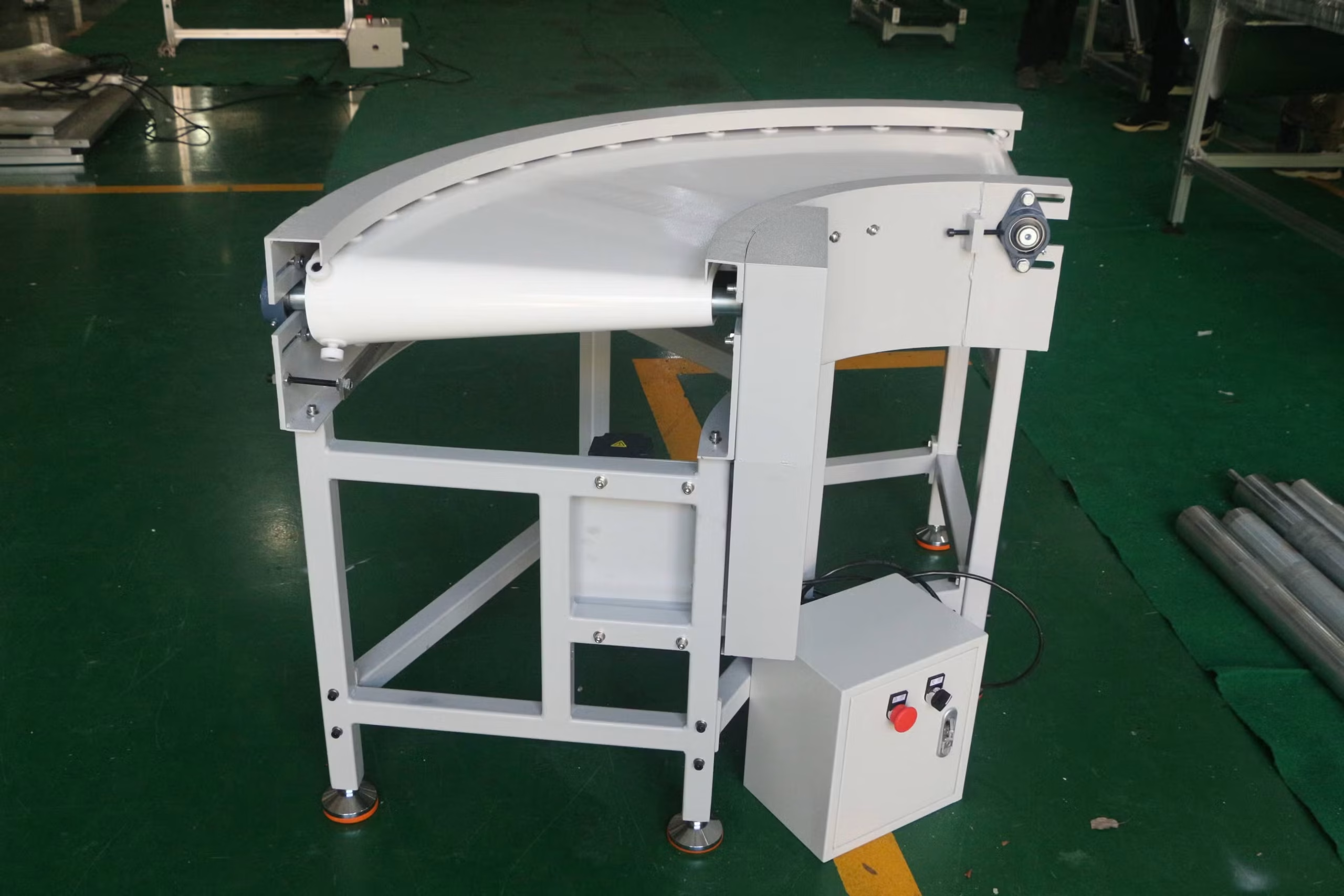

There are several types of Hairise conveyor systems available, each designed to meet specific operational needs. One of the most popular types is the Hairise modular conveyor, which offers a highly flexible and customizable design. The modular nature of this system allows for easy reconfiguration, enabling businesses to adapt the conveyor layout as their production processes change. Another commonly used type is the Hairise belt conveyor, which is ideal for transporting materials over long distances and across varying inclines. The Hairise belt conveyor is particularly suitable for industries where product orientation is critical, as it ensures that items are transported without risk of damage.

For more complex production lines, the Hairise roller conveyor is often used. This system is designed for the efficient transport of heavy or bulky items and is commonly found in industries such as automotive manufacturing and logistics. Additionally, the Hairise modular chain conveyor is an excellent choice for industries that need to handle products with irregular shapes or sizes, as it can accommodate a wide range of materials.

How Hairise Conveyor Enhances Operational Efficiency

The Hairise conveyor enhances operational efficiency in multiple ways. First and foremost, its ability to automate the movement of goods reduces the need for manual labor, allowing employees to focus on more value-added tasks. This automation not only increases production speed but also minimizes the risk of human error, which can lead to costly delays or quality issues. The Hairise conveyor systems are also designed to operate smoothly without frequent interruptions, ensuring that production lines run continuously and without significant downtime.

Moreover, the Hairise conveyor technology is equipped with intelligent control systems that monitor and adjust the speed and direction of the conveyor in real time. This level of precision helps optimize the movement of materials and products, ensuring that they are transported at the right pace for subsequent operations. By reducing delays and optimizing the overall flow of materials, the Hairise conveyor contributes to a more streamlined and efficient manufacturing process.

Customization Options for Hairise Conveyor Systems

The Hairise conveyor offers a wide range of customization options, allowing businesses to tailor the system to their specific needs. One key aspect of this customization is the choice of materials used for the conveyor belts. Depending on the type of product being transported, businesses can select from a variety of belt materials, including PVC, rubber, and stainless steel. This ensures that the Hairise conveyor can handle a wide range of products, from delicate electronics to heavy industrial components.

Another important customization option is the conveyor’s layout. The modular design of the Hairise conveyor allows for flexible configurations, whether it’s a straight line, curved, or multi-lane setup. This versatility makes it easier for businesses to integrate the conveyor system into their existing production lines without the need for extensive modifications. Furthermore, businesses can also choose to incorporate various additional features, such as adjustable speeds, accumulation zones, and integrated sensors for real-time monitoring.

Conclusion

In conclusion, the Hairise conveyor technology is an indispensable tool for industries looking to streamline their operations and improve productivity. With its modular design, advanced features, and ability to handle a wide range of materials, the Hairise conveyor has proven to be a game-changer for businesses across various sectors. By providing a reliable, energy-efficient, and customizable solution, the Hairise conveyor ensures that production processes are smoother, faster, and more cost-effective. Whether you’re in need of a simple conveyor system or a complex, multi-lane setup, the Hairise conveyor can be tailored to meet your specific requirements, helping your business stay competitive in a fast-paced industrial environment.