Raising the Standard of Metal Processing with Automation

In the fast-paced world of industrial manufacturing, precision, speed, and consistency are the foundation of successful production. One of the most vital tools that enable this level of performance is the AUTOMATIC DEBURRING MACHINE. Valgro India, a leading name in surface treatment solutions, has engineered a new generation of machines to meet the rising demand for flawless edge removal. These machines offer high-speed finishing, reducing manual labor while delivering consistent results for a wide range of metal parts and materials.

Why Automated Deburring Has Become a Manufacturing Essential

Traditional deburring methods often depend on manual labor, resulting in inconsistencies, inefficiencies, and increased production time. The AUTOMATIC DEBURRING MACHINE transforms this process by removing burrs and sharp edges with precision-controlled automation. Manufacturers no longer need to compromise between speed and quality. Whether it’s flat sheets, machined parts, or punched components, this machine guarantees uniform results every time, even across high-volume batches.

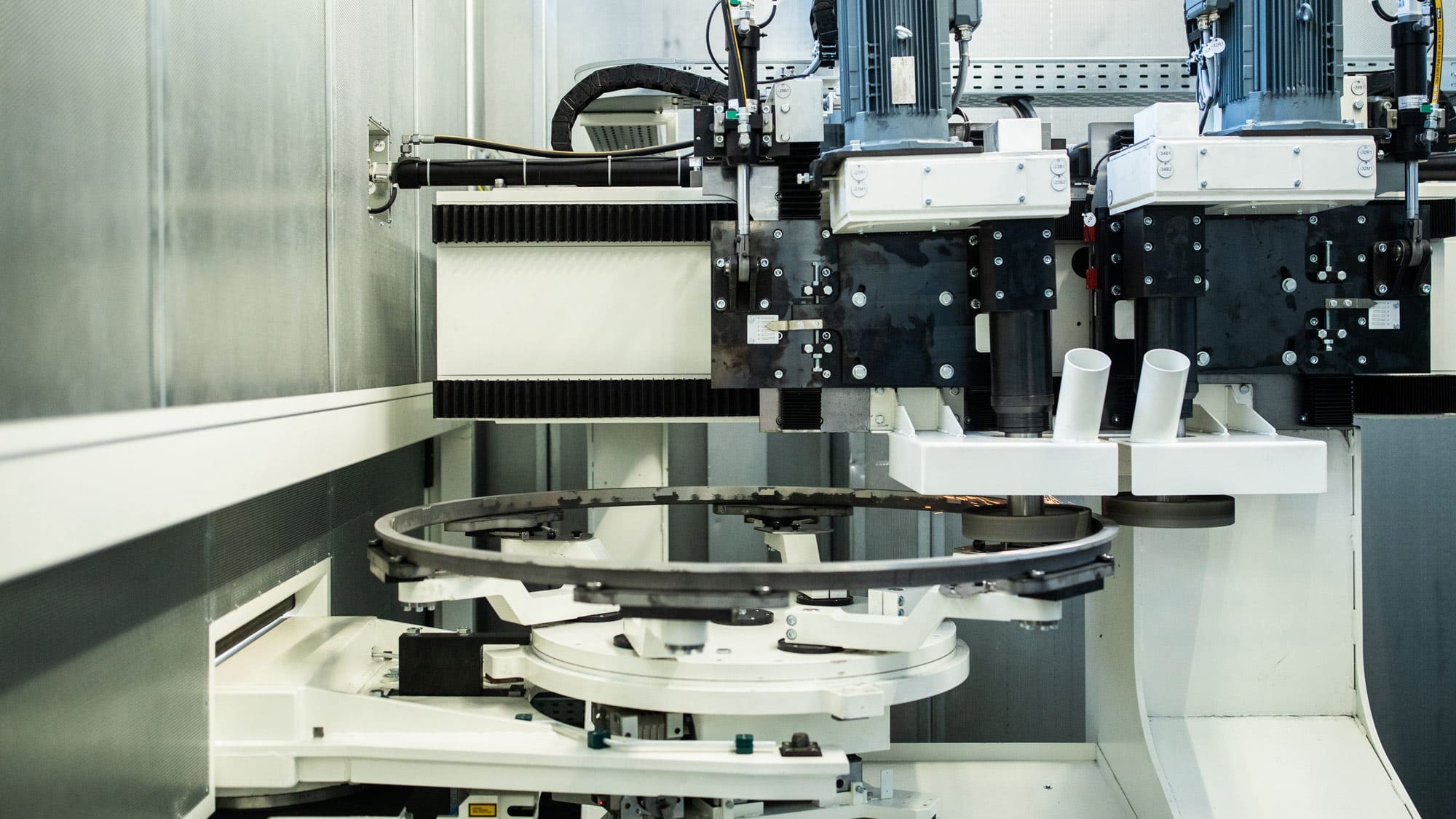

Technology Behind the Precision of Valgro India’s Solutions

The real strength of the AUTOMATIC DEBURRING MACHINE lies in its advanced mechanical design and intelligent programming. Equipped with multi-directional brush heads and adjustable pressure settings, these systems are capable of adapting to different materials and geometries without damaging the workpiece. Valgro India integrates cutting-edge technology that enhances control and customization, allowing users to define edge rounding, burr removal levels, and surface smoothness with pinpoint accuracy.

Meeting Demands Across a Variety of Industries

From aerospace to automotive and electronics to medical device production, the AUTOMATIC DEBURRING MACHINE has found its role across many sectors. Aerospace manufacturers benefit from its ability to deliver ultra-clean and smooth surfaces on complex metal components. Automotive suppliers use the system for engine parts, brake components, and precision gears that require exact tolerances. In electronics, clean edge removal ensures better conductivity and assembly performance. Every industry that values surface perfection benefits from this automation-driven approach.

Unmatched Productivity Through Intelligent Automation

One of the most compelling advantages of the AUTOMATIC DEBURRING MACHINE is its ability to handle large volumes without a decline in output quality. By eliminating the need for manual finishing, the process becomes repeatable and scalable. The machine runs consistently under programmed cycles, ensuring that every workpiece receives identical treatment. This not only reduces human error but also accelerates production time and lowers long-term operating costs.

Durability and Ease of Maintenance

Valgro India understands that industrial machines must withstand continuous operation in demanding environments. Each AUTOMATIC DEBURRING MACHINE is built with robust components, durable construction, and low-maintenance design. Operators benefit from user-friendly control interfaces, easy access to cleaning and maintenance zones, and long-lasting consumables. The design prioritizes uptime, ensuring that production lines remain active with minimal interruptions.

Sustainable Edge Removal for Modern Manufacturing

Sustainability has become a core principle in today’s manufacturing strategies. The AUTOMATIC DEBURRING MACHINE plays its part by reducing material waste, eliminating chemical usage, and supporting energy-efficient operations. Valgro India integrates eco-conscious features into its systems, such as dust collection, optimized power consumption, and reduced noise levels. These machines allow businesses to align their processes with environmental goals without sacrificing performance or precision.

Customization and Support that Drives Efficiency

Valgro India doesn’t offer a one-size-fits-all product. Every AUTOMATIC DEBURRING MACHINE is tailored to meet specific production needs. Whether your application involves thin sheets or thick, complex castings, the machines are engineered to accommodate the exact requirements of your line. In addition to robust customization, Valgro provides full technical support, training, and after-sales service to ensure clients can operate their systems at peak efficiency from day one.

Future-Ready Solutions Backed by Innovation

As manufacturing becomes increasingly digitized, the AUTOMATIC DEBURRING MACHINE is evolving with smart features, digital controls, and integration-ready designs. Valgro India is investing in the future by adding capabilities such as data monitoring, remote diagnostics, and real-time performance tracking. These innovations give manufacturers deeper insights into their processes, allowing smarter decision-making and faster responses to production changes.

Conclusion – Consistent Performance, Accelerated Results

The AUTOMATIC DEBURRING MACHINE from Valgro India is more than just equipment — it is a powerful enabler of modern production goals. Offering unmatched consistency, faster throughput, and edge finishing excellence, it empowers manufacturers to meet high standards with confidence. As demand for clean, burr-free components continues to rise, investing in automation is no longer a luxury — it’s a necessity. Valgro India stands ready to lead the way with technology that shapes the future of edge removal.